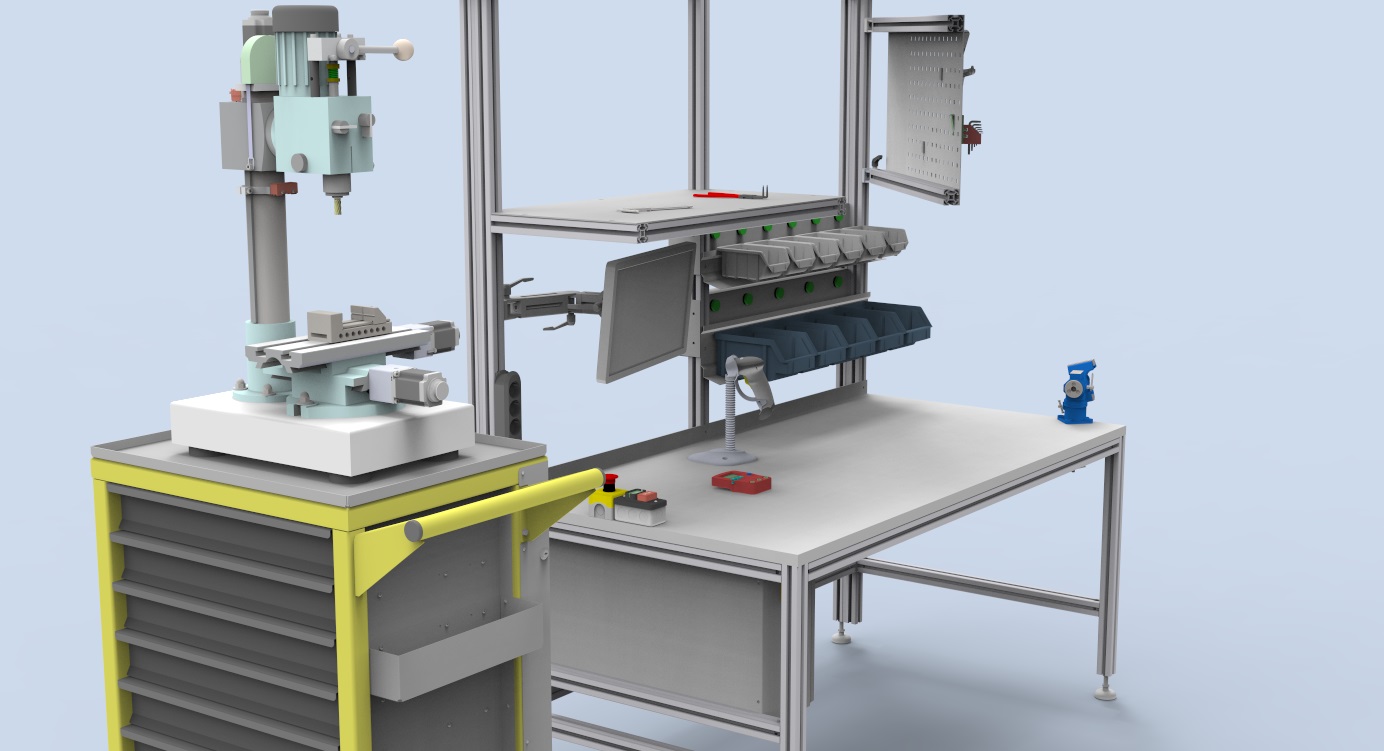

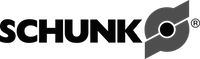

MECHANICAL FRAME ASSEMBLY STATION

The purpose of the mechanical frame assembly station is to assemble the mechanical frame and main units of the hospital robot family quickly and with guaranteed accuracy from the prepared units, helping to ensure that the device is marketed in the appropriate quality.

The station's software system keeps statistics on the assembly process, jams and missing parts. The assembly process can be started automatically or stopped immediately from the user interface.

The following assembly processes can be performed on the device:

- assembly of parts

- component dosing

- insertion of metal and plastic parts

- integrity testing

- optical camera inspection

The assembly process is controlled by operation control software that meets the following requirements through a graphical interface:

- Product selection: the device is capable of storing the assembly process of multiple products and provides a graphical interface for selecting between processes.

- Setting up the product assembly process: the device is able to learn the positions of each assembly point and the order of the assembly points by moving the assembly heads by hand.

- Emergency stop button: there is an easily accessible emergency stop button on the user interface, which can be used to quickly interrupt the assembly operation in the event of a malfunction.

- Image documentation: at the end of each assembly process, the device takes a photo of the condition, which is stored in a separate database entry for each product. For a malfunctioning product, you can speed up troubleshooting by checking your photos.

- Optical fault detection: optical fault detection based on self-learning algorithm with associated software and camera

- Assembly Process Logging: In addition to the visual documentation, the tool logs all assembly steps that have been completed correctly or incorrectly, with an exact time, which is also stored in a separate database entry for each completed product. In addition, the device logs any unexpected events that affect the assembly work: start, stop assembly, missing parts, waiting for operator, assembly error, device error, program error, authorization error, and so on.

The following assembly processes can be performed on the device:

- assembly of parts

- component dosing

- insertion of metal and plastic parts

- integrity testing

- optical camera inspection

The assembly process is controlled by operation control software that meets

the following requirements through a graphical interface:

- product selection

- setting up the product assembly process

- emergency stop button

- pictorial documentation

- optical fault detection

- assembly process logging

Technical parameters:

Power supply: 230V AC, 3-6 A

Operating temperature: 10-45 ° C

Space requirement: 180x130x200 cm (length x width x height)

Noise level: <100 dB

Control: industrial PC, integrated industrial PC

Interface: graphical user interface Graphical

Mounting head movement: X-Y-Z linear positioning

Positioning accuracy: <+ - 0.05mm

Number of interchangeable screwdriver bits: 5-20

Screw dosing type: manual / vibrating dosing

Logging: data recording

Database: MySQL database

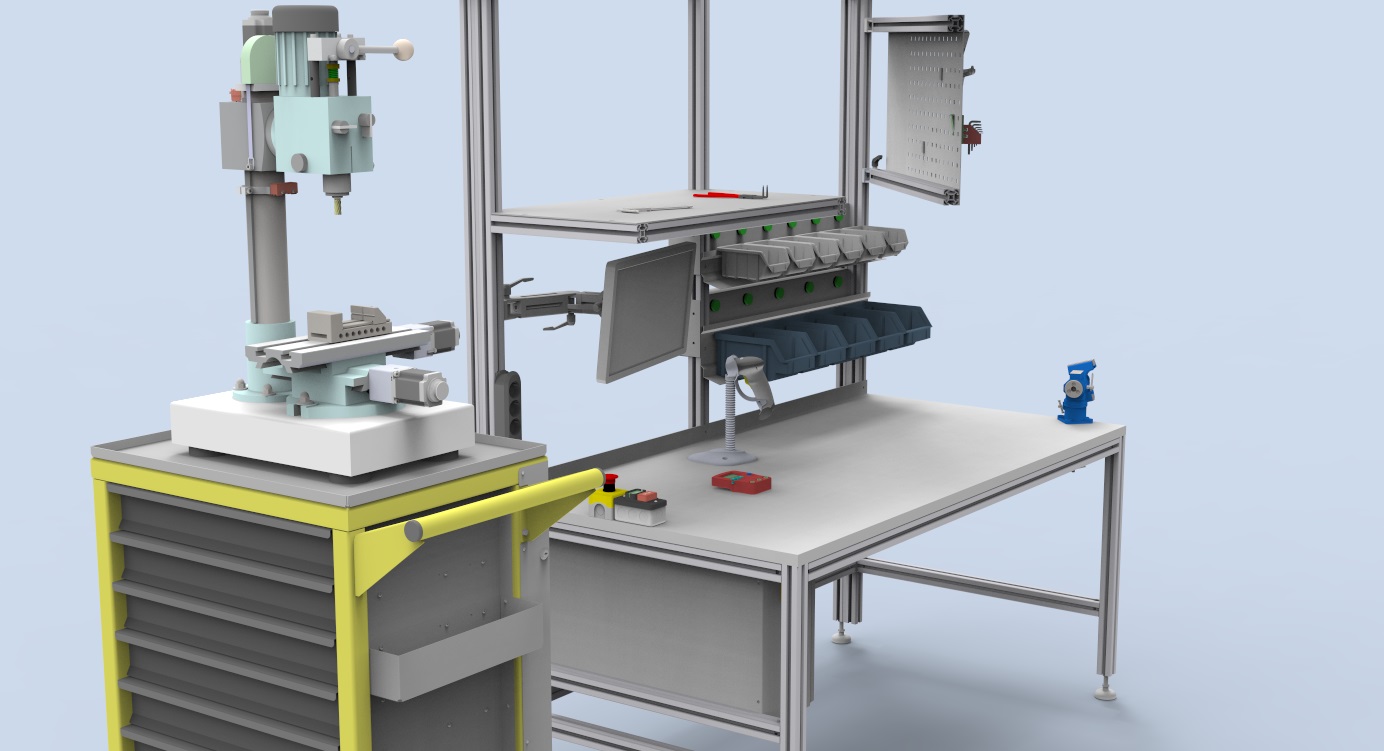

BATTERY ASSEMBLY LINE

The purpose of custom battery assembly stations is to assemble the batteries that power the hospital robot family quickly, with guaranteed accuracy, from the prefabricated units, helping to ensure that the device is marketed in the right quality.

The station's software system keeps statistics on the assembly process, jams and missing parts. The assembly process can be started automatically or stopped immediately from the user interface. The following assembly processes can be performed on the device:

- assembly of parts

- component dosing

- insertion of metal and plastic parts

- integrity testing

- optical camera inspection

The assembly process is controlled by operation control software that meets the following requirements through a graphical interface:

- Product selection: the device is able to store the assembly process of multiple products and provides a graphical interface for choosing between the processes.

- Setting up the product assembly process: the device is able to learn the positions of each assembly point and the order of the assembly points by moving the assembly heads by hand.

- Emergency stop button: there is an easily accessible emergency stop button on the user interface, which can be used to quickly interrupt the assembly operation in the event of a malfunction.

- Image documentation: at the end of each assembly process, the device takes a photo of the specific assembly condition, which is stored in a separate database entry for each completed product. This speeds up troubleshooting with a photo for a malfunctioning product.

- Optical fault detection: optical fault detection based on self-learning algorithm with associated software and camera

- Assembly Process Logging: in addition to the visual documentation, the tool logs each well or incorrectly completed assembly step with an exact time, which it also stores in a separate database entry for each finished product. In addition, the device logs any unexpected events that affect the assembly work: start, stop assembly, missing parts, waiting for operator, assembly error, device error, program error, authorization error, and so on.

The assembly process can be started automatically or stopped immediately from the user interface of the assembly station. The following assembly processes can be performed on the device:

- assembly of parts

- component dosing

- insertion of metal and plastic parts

- integrity testing

- optical camera inspection

Optical error detection:

- optical error detection based on self-learning algorithm with associated software and camera

- Assembly process logging: In addition to the visual documentation, the device logs all assembly steps that have been completed correctly or incorrectly at an accurate time.

Technical parameters:

Power supply: 230V AC, 3-6 A

Operating temperature: 10-45 ° C

Space requirement: 180x130x200 cm (length x width x height)

Noise level: <100 dB

Control: industrial PC, integrated industrial PC

Interface: graphical user interface Graphical

Mounting head movement: X-Y-Z linear positioning

Positioning accuracy: <+ - 0.05mm

Number of interchangeable screwdriver bits: 5-20

Screw dosing type: manual / vibrating dosing

Logging: data recording

Database: MySQL database

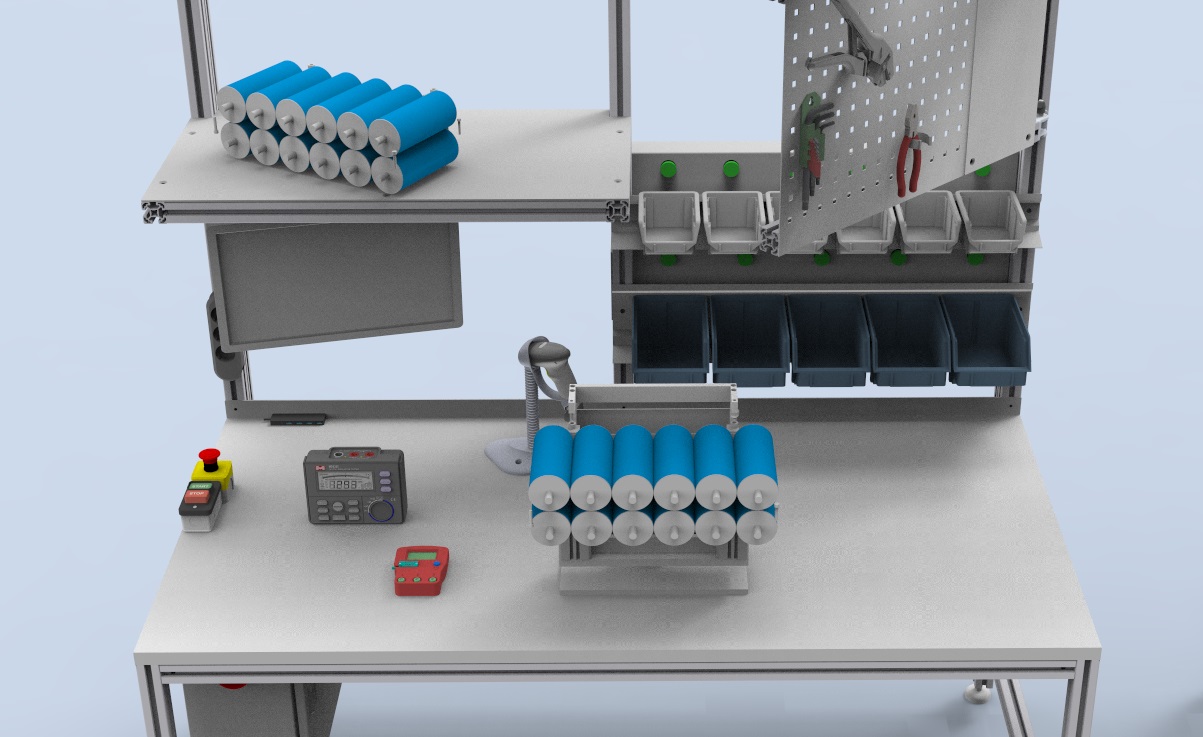

ELECTRONICS TESTING EQUIPMENT

Test station for inspecting the operation of electrical contacts and electronic components

- verifying the successful implantation of electrical components by two-point voltage measurement

- checking the adequacy of insulation

- measuring and checking the current consumption of an electronic unit

- performance measurement

- visual display of results

- test analytics, scrap analysis, software result processing

Enclosure size: 150x120x200 cm (length x width x height)

Mains supply: ~ 230 V AC, 50 Hz, 32 A

Operating temperature: 10 - 40 ° C

Warranty: 3 years